当社は、非線形有限要素法構造解析の技術系解析コンサルティング会社です。

株式会社ランスモアのホームページへようこそ。

No.429 Non-linear buckling analysis of thin-walled cylinder being subjected to axial compressive load

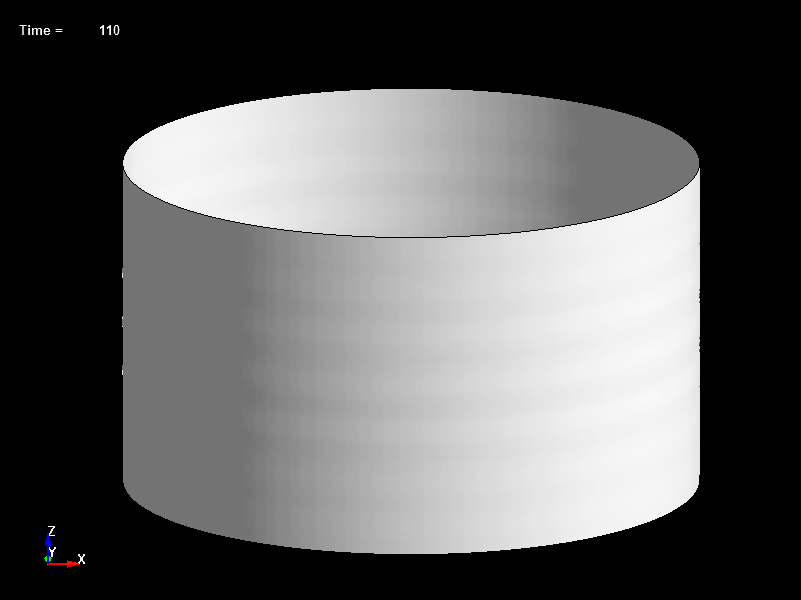

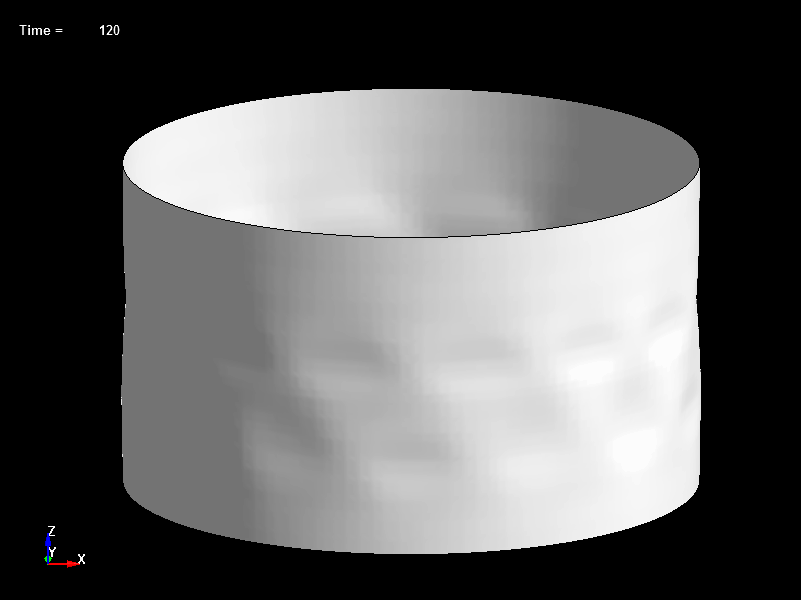

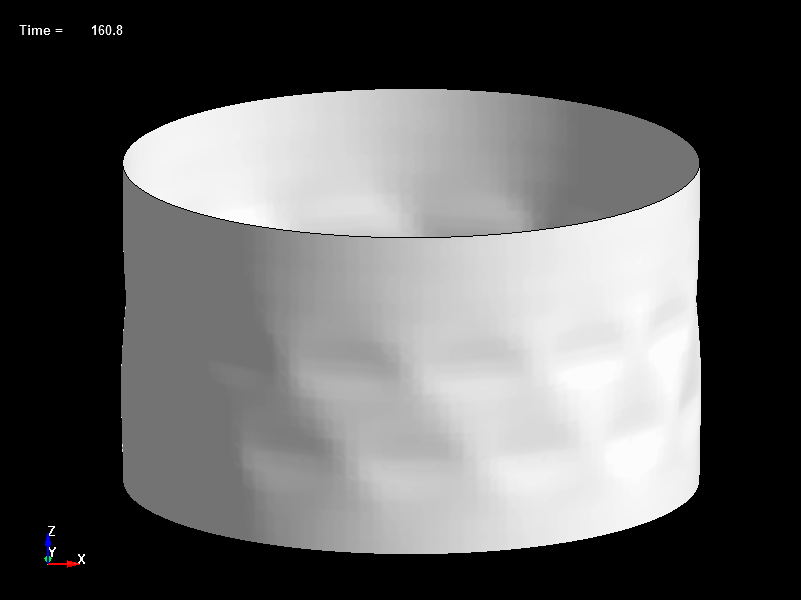

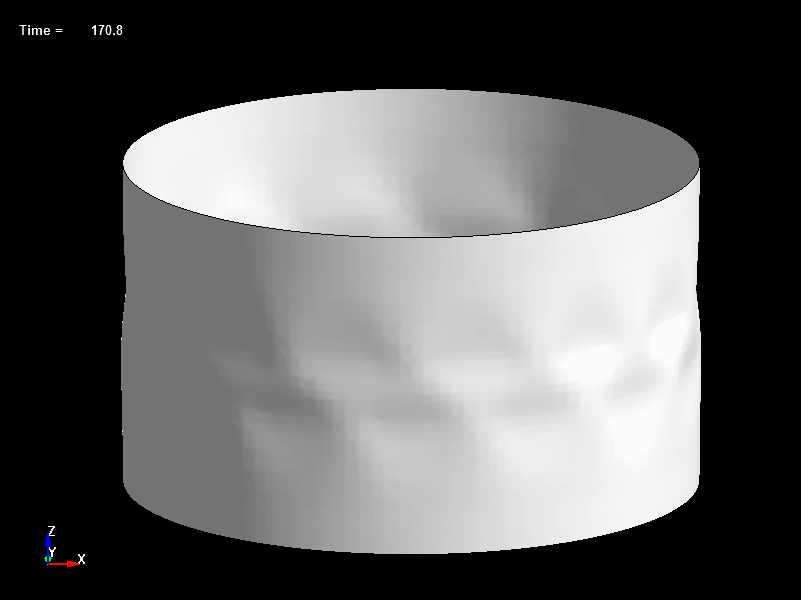

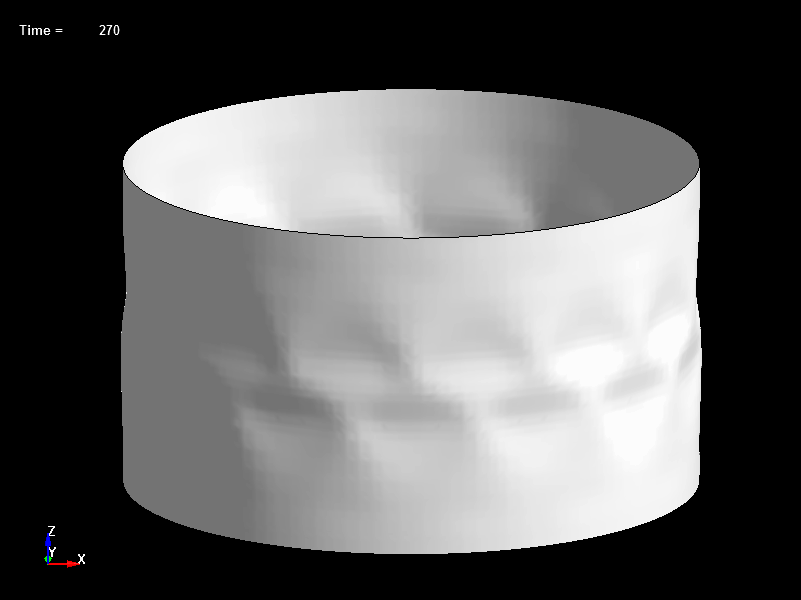

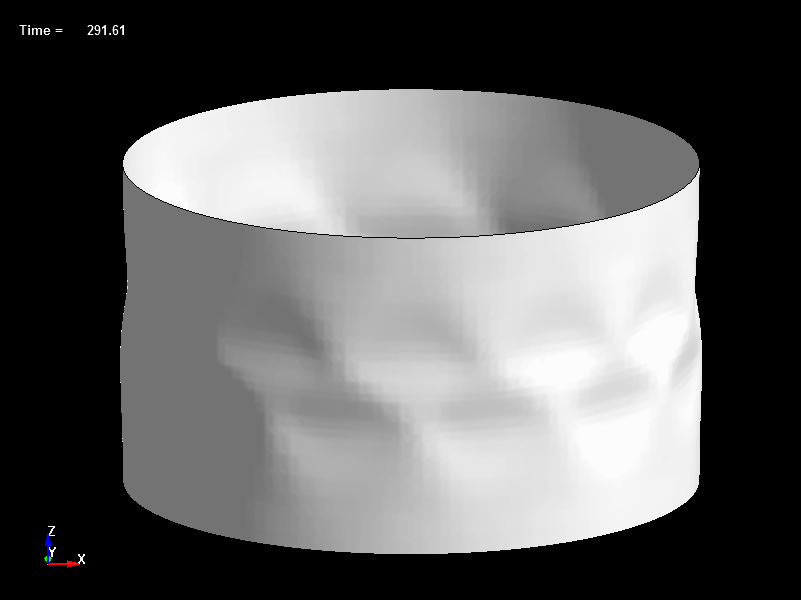

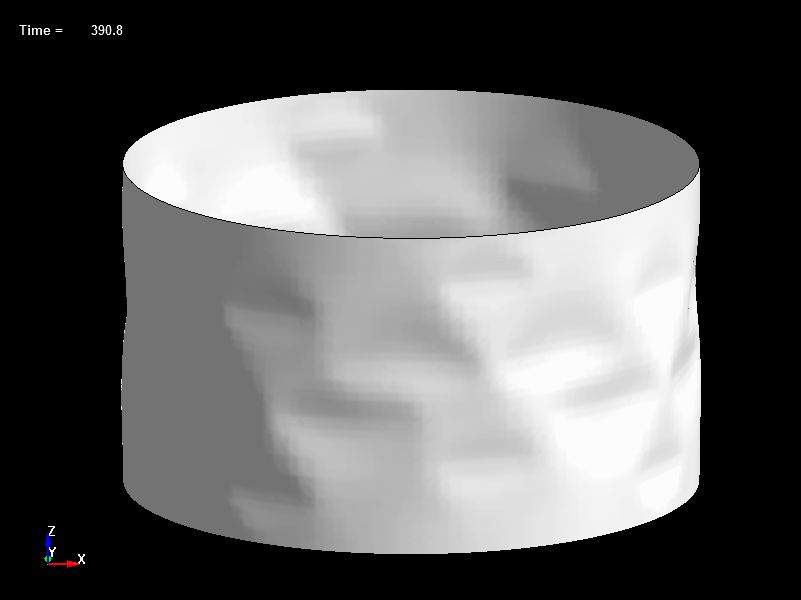

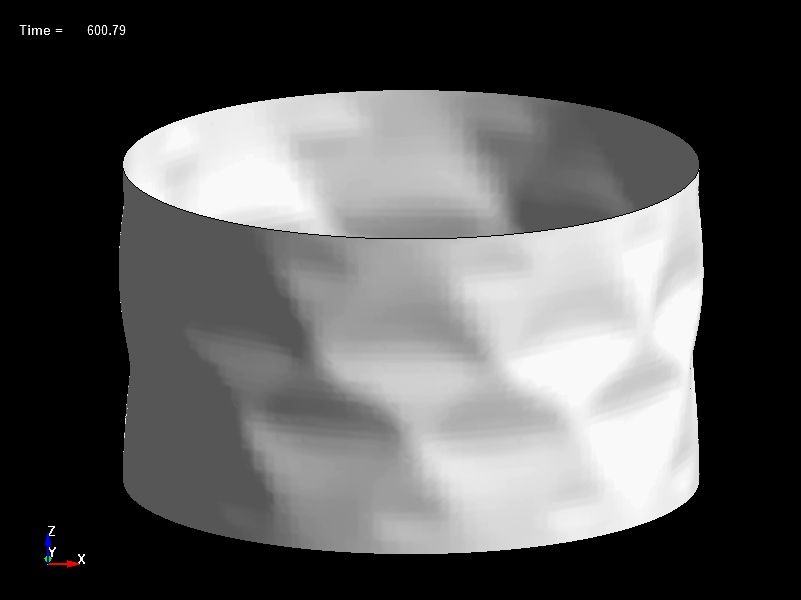

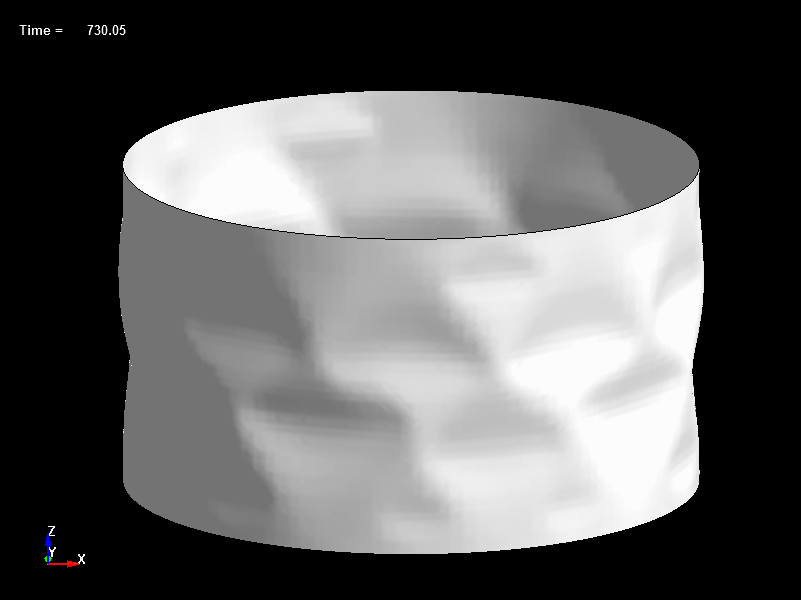

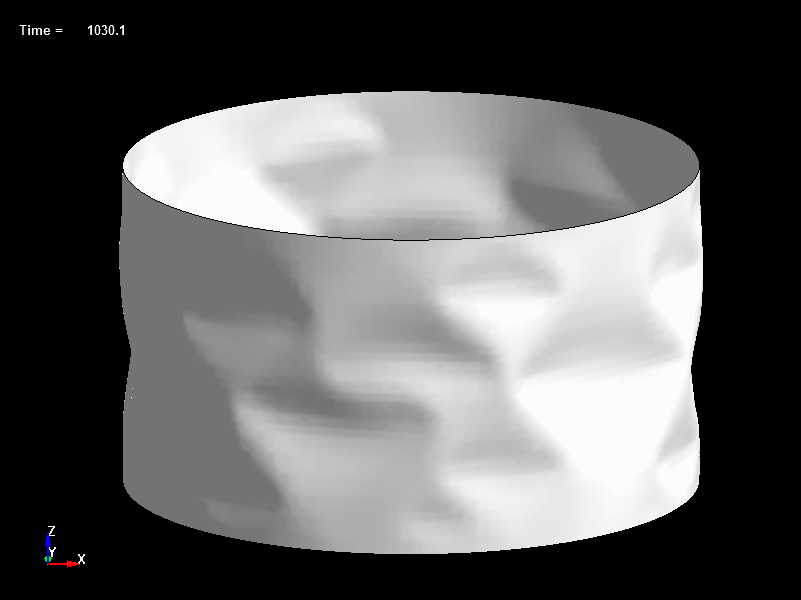

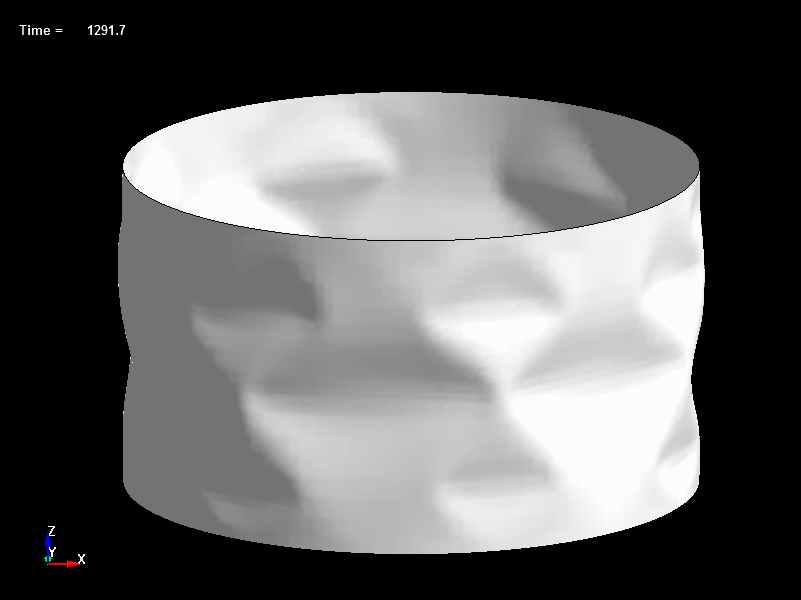

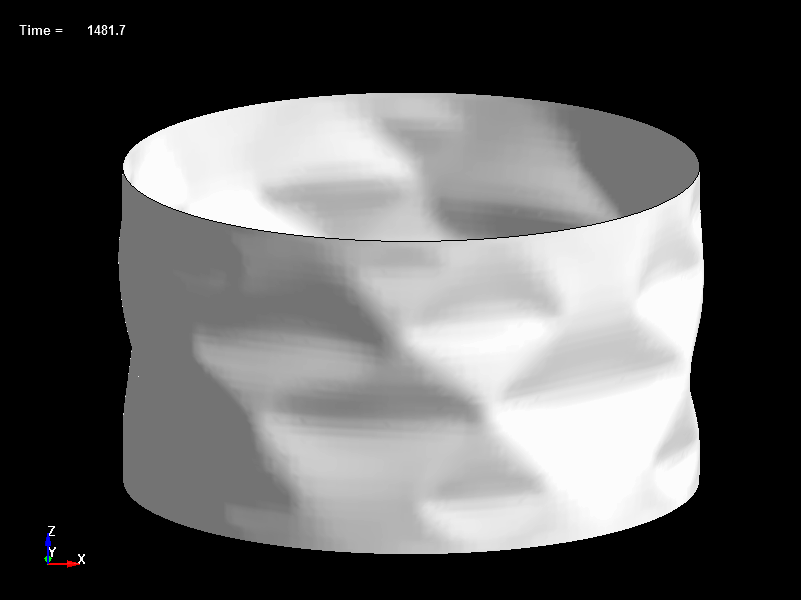

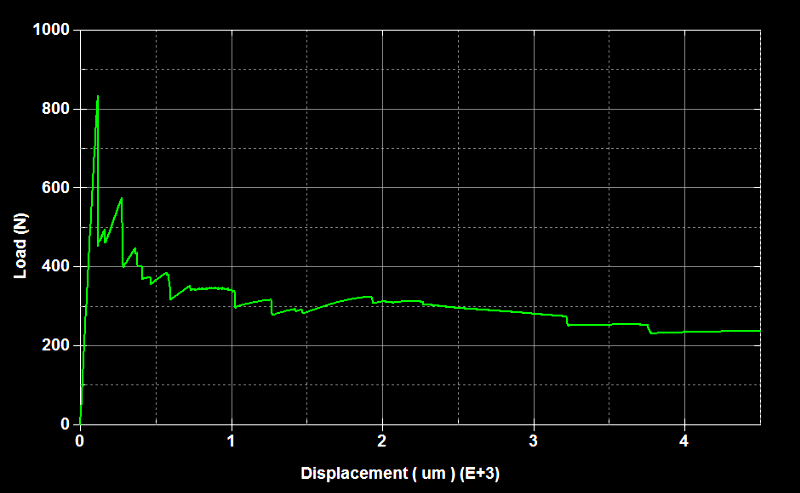

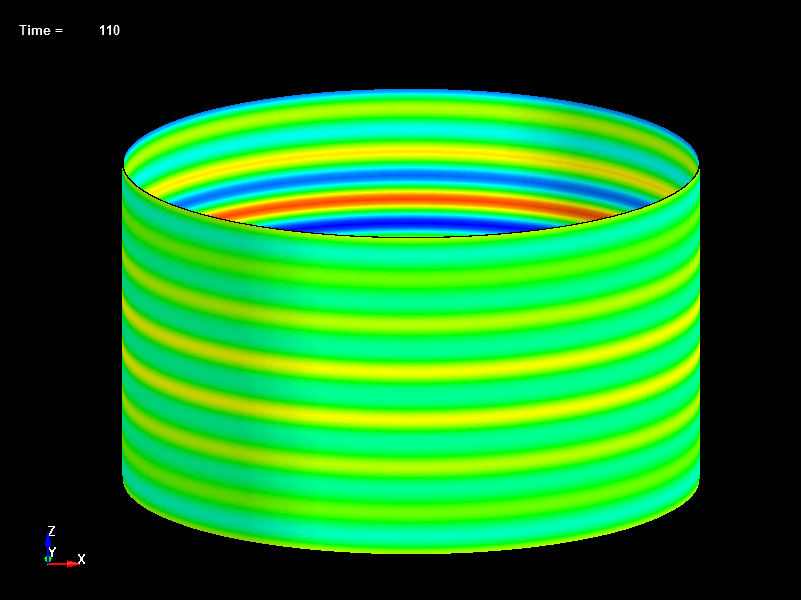

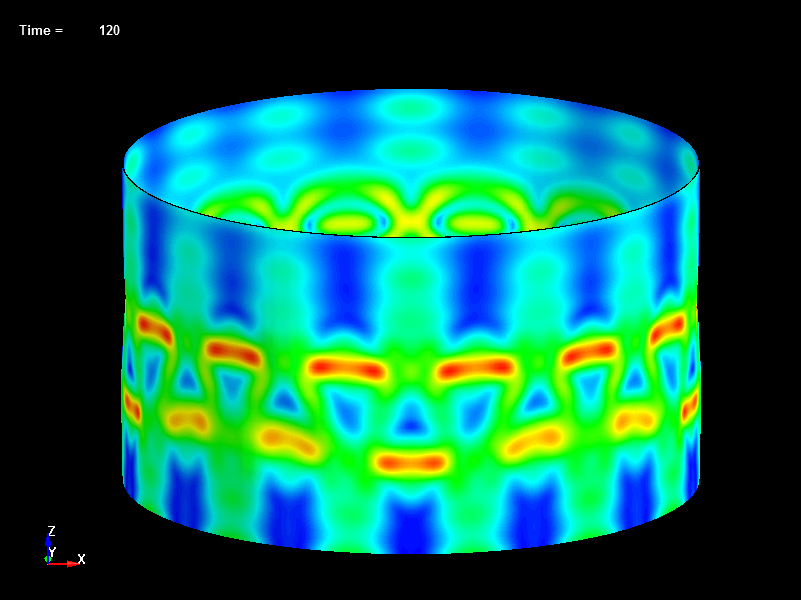

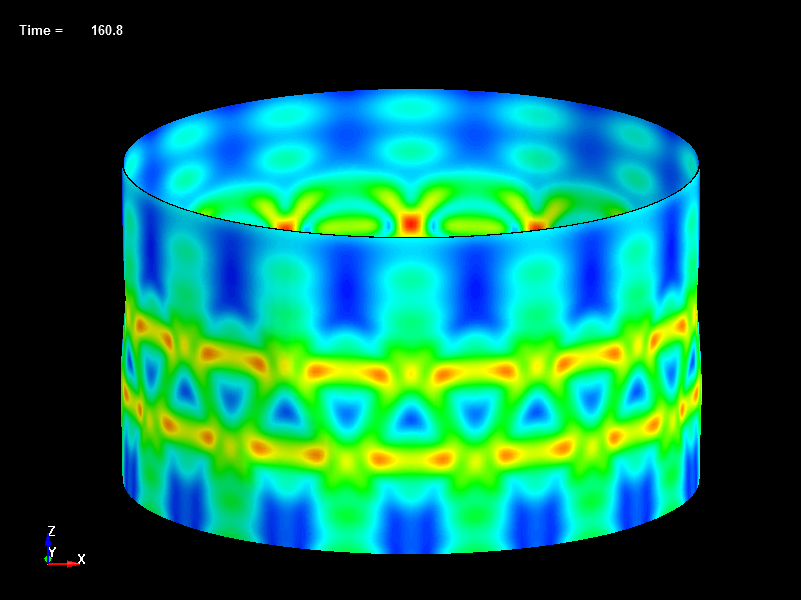

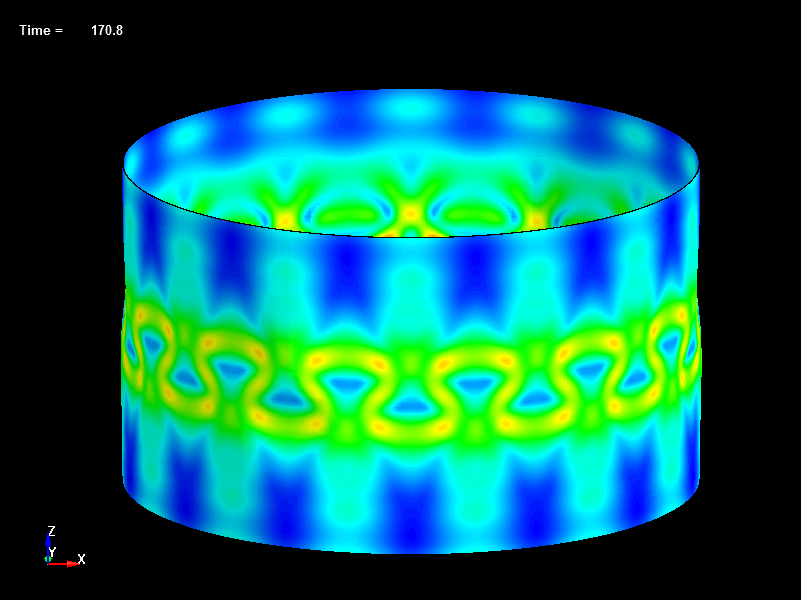

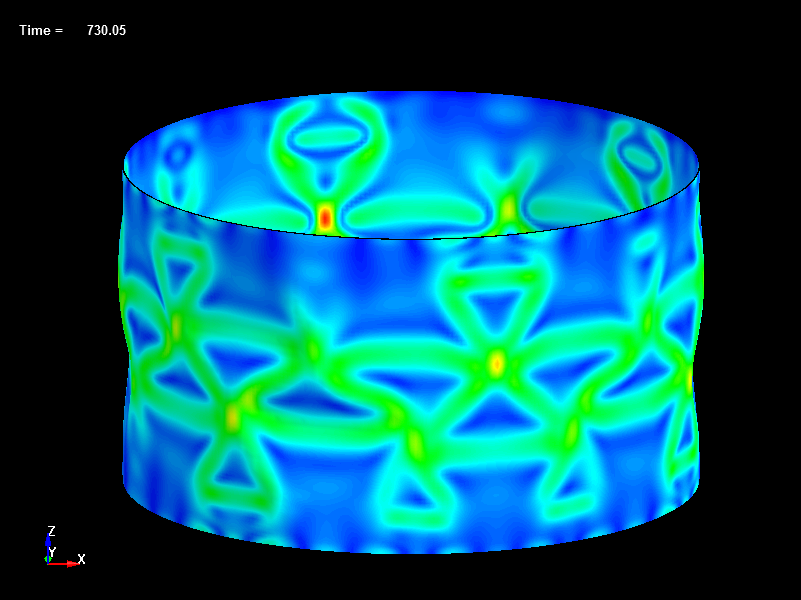

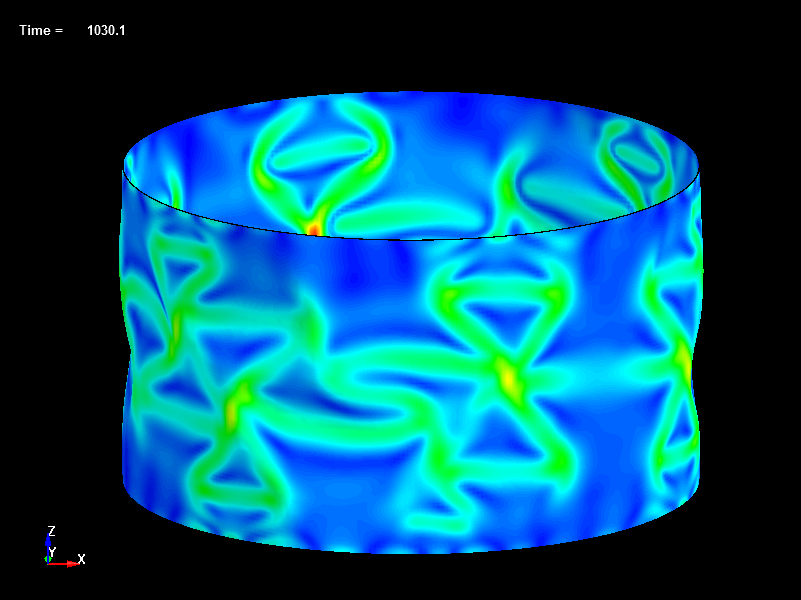

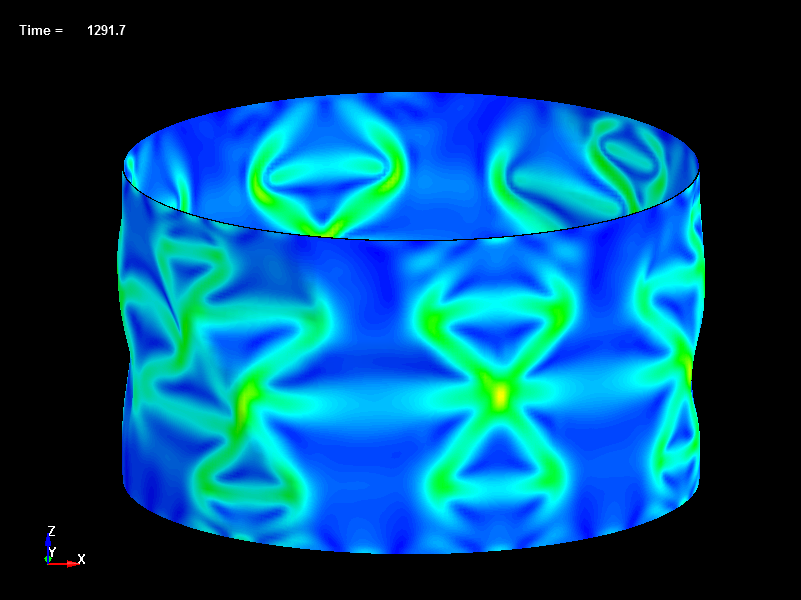

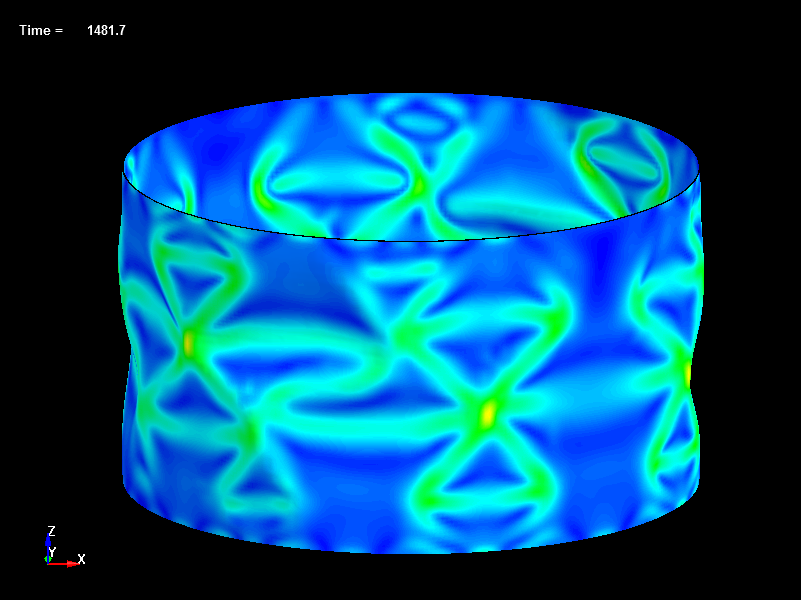

例題283 Buckling mode analysis で参考にした論文で検討された圧縮荷重を受けた薄肉円筒の非線形座屈解析をLS-DYNAの陰解法でシミュレーションしました。 Reference1:三原, 小林, 藤井:軸圧縮を受ける弾性円筒シェルの後座屈解析, 日本機械学会論文集(A編) 77巻776号(2011-4) Reference2: Yamaki, N., elastic stability of circular cylindrical shells(1984), p.230, p.433, North-Holland. 解析条件:円筒の直径 D=200mm, 肉厚 t=0.247mm, 高さ H=113.9mm, ヤング率 E=5560MPa, ポアソン比 Nu=0.30 円筒の下端部を変位完全拘束し、上端部を下方向に圧縮させた際に円筒に生じる座屈変形挙動をLS-DYNAの陰解法機能を使用して解析しました。 円筒は初期は弾性座屈の臨界荷重に達すると座屈し急激に耐荷重が低下します。変形が進むと新たな座屈モードに次々と飛び移りながらシフトしていきます。

Keywords: Postbuckling Analysis, Non-Linear Implicit LS-DYNA, *Section_shell elform=10(BWC)

Tool: LS-PrePost ver.4.3, LS-DYNA SMP Double Precision R800 Win64

なお,本事例はサンプルであることをご了承下さい。

December-25-2015 June-16-2020 update

Fig.1 Disp=0.11mm, Load=791N

Fig.2 Disp=0.12mm, Load=453N

Fig.3 Disp=0.16mm, Load=492N

Fig.4 Disp=0.17mm, Load=466N

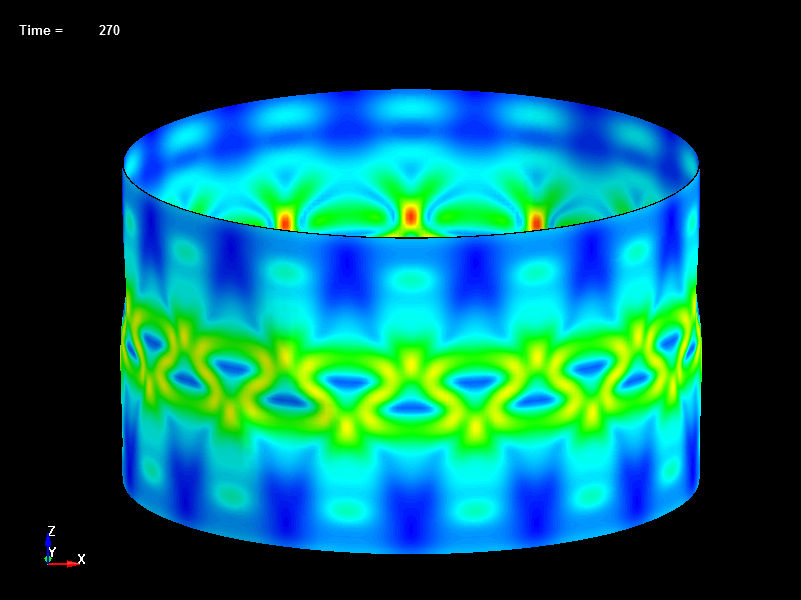

Fig.5 Disp=0.27mm, Load=570N

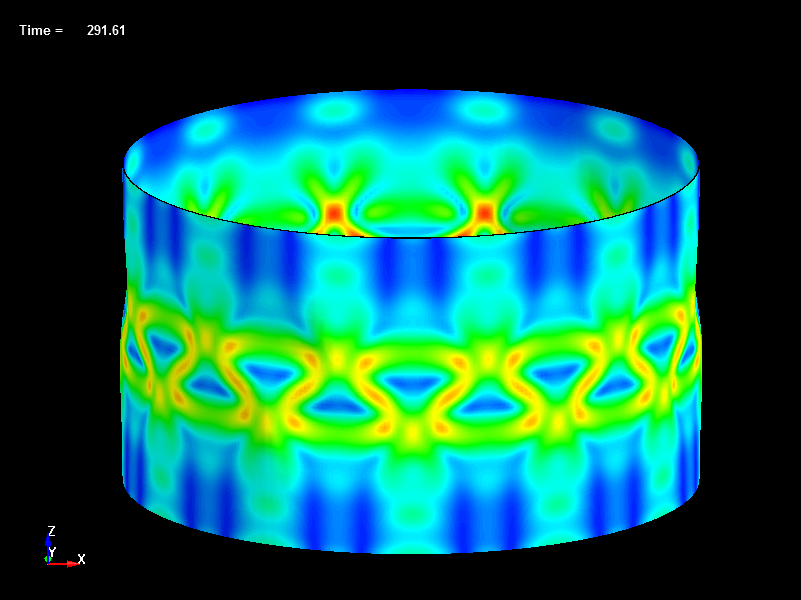

Fig.6 Disp=0.29mm, Load=404N

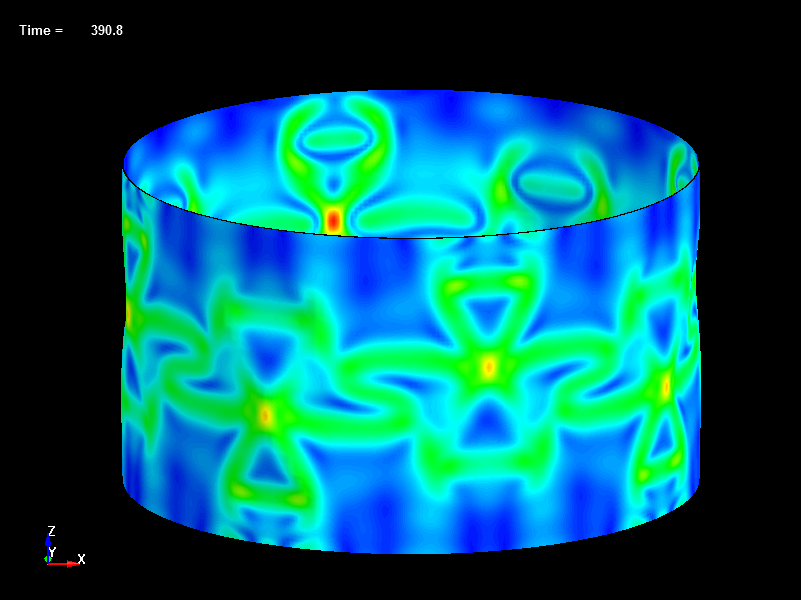

Fig.7 Disp=0.39mm, Load=402N

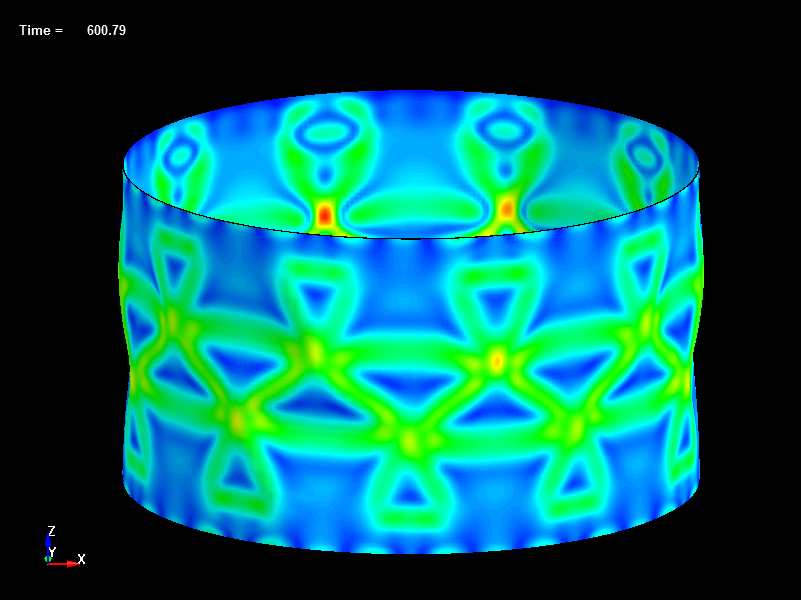

Fig.8 Disp=0.60mm, Load=317N

Fig.9 Disp=0.73mm, Load=341N

Fig.10 Disp=1.03mm, Load=296N

Fig.11 Disp=1.29mm, Load=281N

Fig.12 Disp=1.48mm, Load=282N

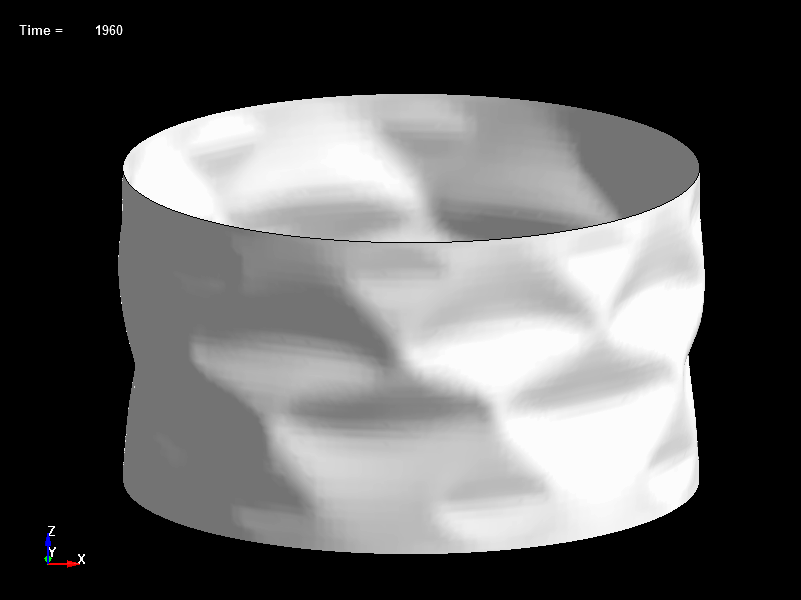

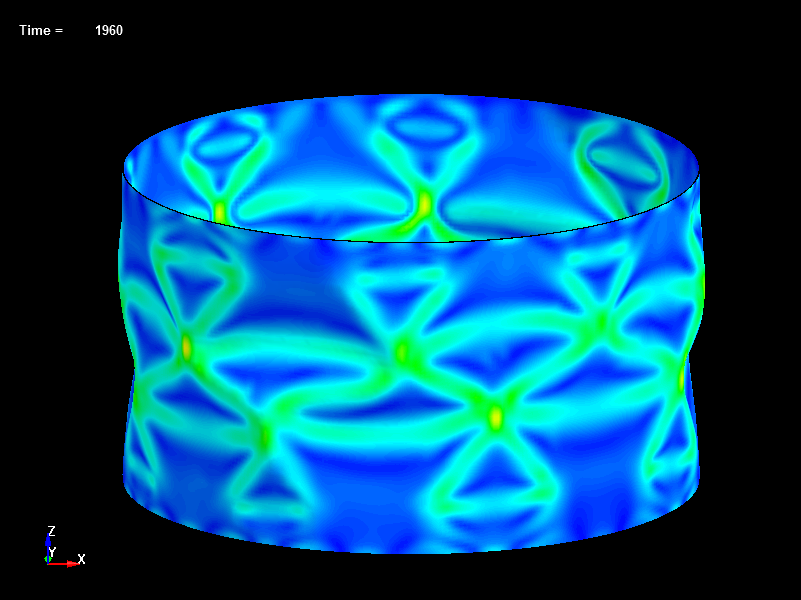

Fig.13 Disp=1.96mm, Load=309N

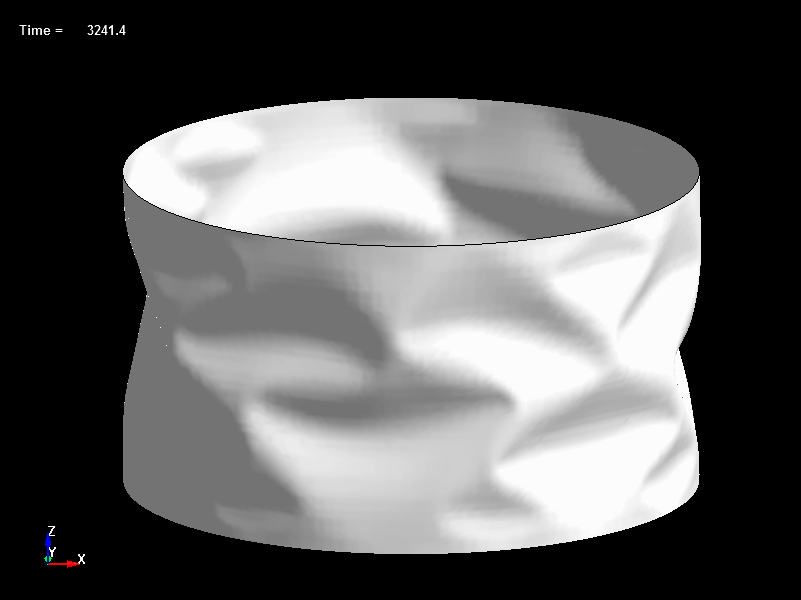

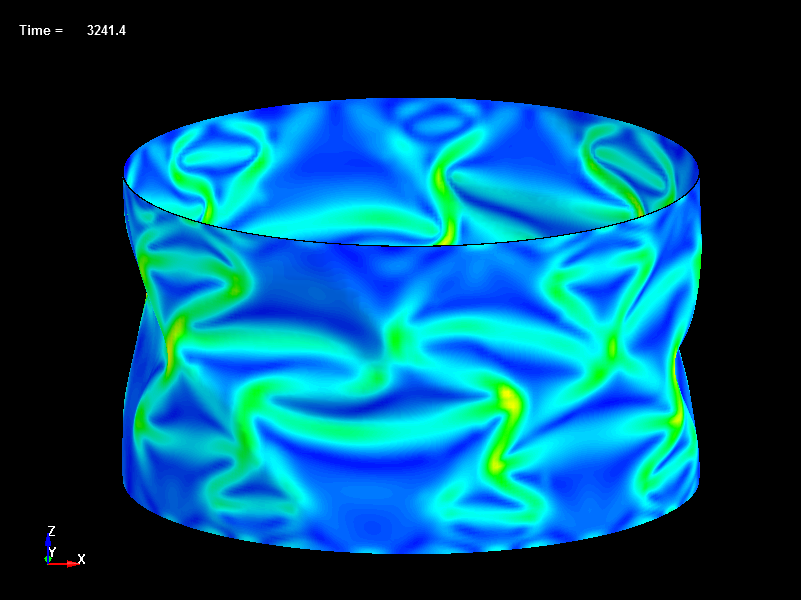

Fig.14 Disp=3.24mm, Load=251N

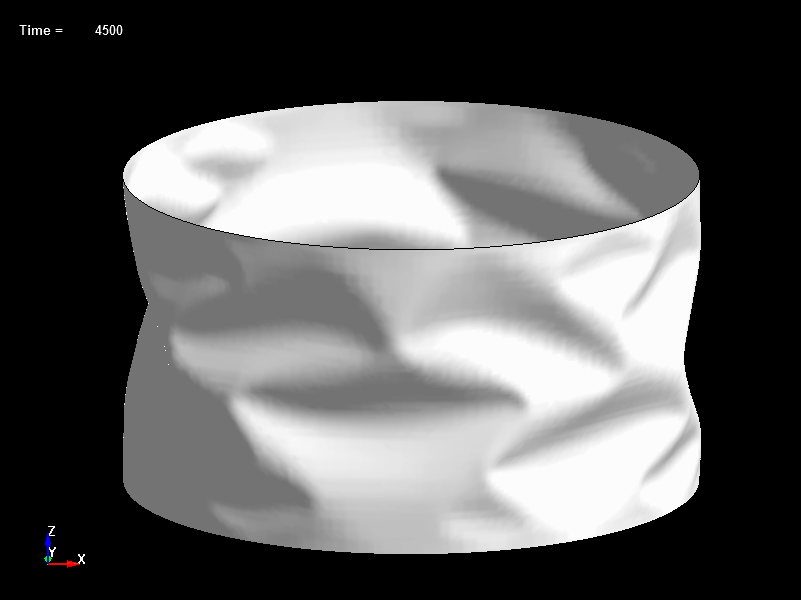

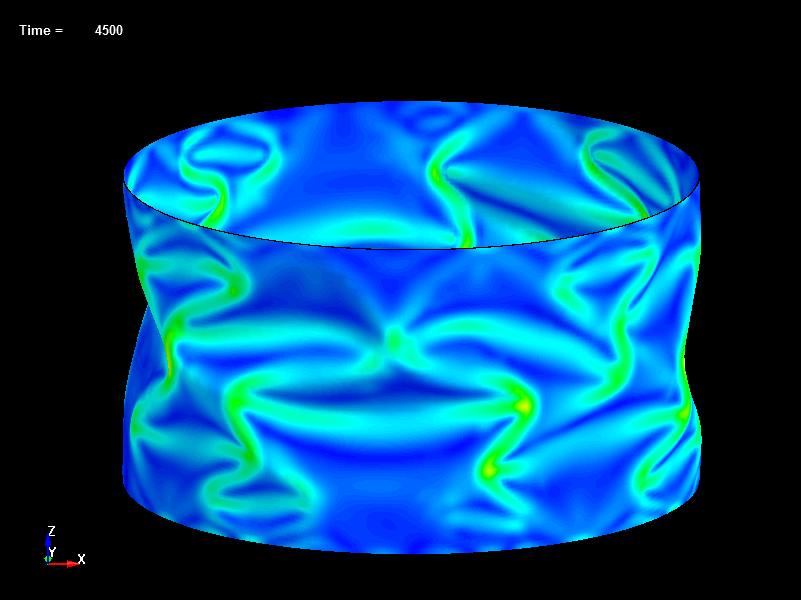

Fig.15 Disp=4.50mm, Load=237N

Fig.16 Graph X-Axis : Displacement (micro-meter), Y-Axis : Load (N)

Fig.17 Disp=0.11mm, Load=791N, Effective Stress

Fig.18 Disp=0.12mm, Load=453N, Effective Stress

Fig.19 Disp=0.16mm, Load=492N, Effective Stress

Fig.20 Disp=0.17mm, Load=466N, Effective Stress

Fig.21 Disp=0.27mm, Load=570N, Effective Stress

Fig.22 Disp=0.29mm, Load=404N, Effective Stress

Fig.23 Disp=0.39mm, Load=402N, Effective Stress

Fig.24 Disp=0.60mm, Load=317N, Effective Stress

Fig.25 Disp=0.73mm, Load=341N, Effective Stress

Fig.26 Disp=1.03mm, Load=296N, Effective Stress

Fig.27 Disp=1.29mm, Load=281N, Effective Stress

Fig.28 Disp=1.48mm, Load=282N, Effective Stress

Fig.29 Disp=1.96mm, Load=309N, Effective Stress

Fig.30 Disp=3.24mm, Load=251N, Effective Stress

Fig.31 Disp=4.5mm, Load=237N, Effective Stress